What is TPU Material?

Thermoplastic polyurethane (TPU) is any of a class of polyurethane plastics with many properties, including elasticity, transparency, and resistance to oil, grease and abrasion. Technically, they are thermoplastic elastomers consisting of linear segmented block copolymers composed of hard and soft segments.

Chemistry

TPU is a block copolymer consisting of

alternating sequences of hard and soft segments or domains formed by the

reaction of diisocyanates with short-chain diols (so-called chain extenders)

and diisocyanates with long-chain diols. By varying the ratio, structure and/or

molecular weight of the reaction compounds, an enormous variety of different

TPU can be produced. This allows urethane chemists to fine-tune the polymer's

structure to the desired final properties of the material. For example, a

greater ratio of hard to soft segments will result in a more rigid TPU, while

the reverse is also true.

Morphology

The final resin consists of linear

polymeric chains in block-structures. Such chains contain low polarity segments

which are rather long (called soft segments), alternating with shorter, high

polarity segments (called hard segments). Both types of segments are linked

together by covalent links so that they actually form block-copolymers.

The polarity of the hard pieces creates a

strong attraction between them, which causes a high degree of aggregation and

order in this phase, forming [[crystal] a]line or pseudo crystalline areas

located in a soft and flexible matrix. This so-called phase separation between

both blocks can be more or less important, depending on the polarity and the

molecular weight of the flexible chain, the production conditions, etc. The

crystalline or pseudo crystalline areas act as physical cross-links, which

account for the high elasticity level of TPU, whereas the flexible chains will

impart the elongation characteristics to the polymer.

These "pseudo crosslinks",

however, disappear under the effect of heat, and thus the classical extrusion,

injection molding and calendaring processing methods are applicable to these

materials. Consequently, TPU scrap can be reprocessed.

Uses

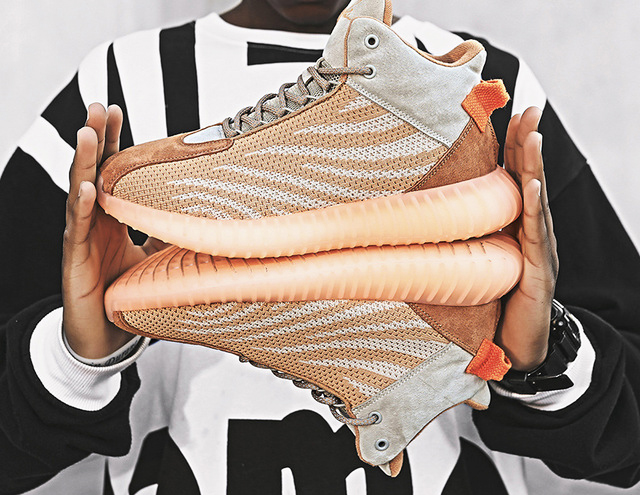

TPU has many applications including

automotive instrument panels, caster wheels, power tools, sporting goods,

medical devices, drive belts, footwear, inflatable rafts, and a variety of

extruded film, sheet and profile applications.TPU is also a popular material

found in outer cases of mobile electronic devices, such as mobile phones. It is

also used to make keyboard protectors for laptops.

TPU is well known for its applications in

performance films, wire and cable jacketing, hose and tube, in adhesive and

textile coating applications and as an impact modifier of other polymers.

TPU is a common filament material for use

in fused filament fabrication 3D printing due to the fact that it is an elastic

thermoplastic which makes it ideal for printing objects that need to be

flexible and elastic.[citation needed] The fact that TPU is a thermoplastic

also allows it to be melted, extruded, then cooled back into a solid which is

necessary when 3D printing using fused filament fabrication.

Overview of TPU on the market

Properties of commercially available TPU

include:

• HIGH ABRASION RESISTANCE

• LOW-TEMPERATURE PERFORMANCE

• HIGH SHEAR STRENGTH

• HIGH ELASTICITY

• TRANSPARENCY

• OIL AND GREASE RESISTANCE

- Company Info

- About Us

- Contact Us

- Customer Reviews

- Company Blog

- Company Policies

- Payment & Shipping

- Sitemap

- How to Order?

- FAQs

- User Center

- Easy Login or Register

- My Account

- My Orders

- Forget Password

- Tracking Orders

- Leave a Message Online

- Submit a Product

- Newsletter

-

Subscribe for Updates. We'll let you know about the latest deals & newest products.

- Join our community

Copyright © 2024 VEASOON . All Rights Reserved.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()